|

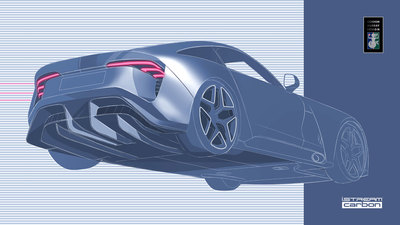

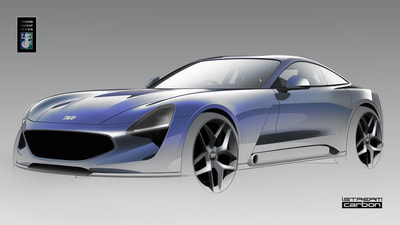

The team at Gordon Murray Design have worked very closely with the TVR team to deliver a vehicle which meets all the class-leading and exacting criteria set-down by TVR which has resulted in a vehicle which sets new standards for weight and torsional stiffness.

TVR chose Gordon Murray Design’s iStream® carbon manufacturing system to help deliver these outstanding performance values. iStream® carbon is Gordon Murray Design’s premium version of iStream® and it brings Formula One technology and materials within reach of the everyday motorist. This technology has been the enabler in producing a sports car some 300kg lighter than its class opposition alongside delivering new levels of torsional rigidity. The new car brings new standards of engineering and quality to TVR products and the world-class design and prototyping team have worked very closely with the two UK companies who both share Gordon Murray Design’s drive towards producing engineering product to exacting standards. Chasestead engineering and Formaplex have played a great role in the production of the sports car. The Goodwood Revival is therefore a double British celebration – the re-launch of iStream® carbon. Professor Gordon Murray says “We at Gordon Murray Design are very proud to be associated with a fantastic British product and so many excellent UK companies and I would like to be the first to congratulate TVR on their 70th Anniversary and the launch of this product. The iStream® assembly process is a complete rethink and redesign of the traditional automotive manufacturing process and could potentially be the biggest revolution in high volume manufacture since the Model T. Development of the process began over 15 years ago and it has already won the prestigious ‘Idea of the Year’ award from Autocar who were given privileged access in order to make their assessment. The simplified assembly process means that the manufacturing plant can be designed to be 20% of the size of a conventional factory. This could reduce capital investment in the assembly plant by approximately 80%. Yet the flexibility of this assembly process means that the same factory could be used to manufacture different variants. The iStream® design process is a complete re-think on high volume materials, as well as the manufacturing process and will lead to a significant reduction in full lifecycle CO2. For more information please visit www.istreamtechnology.co.uk Comments are closed.

|

Categories

All

News Archives

July 2024

|

- Home

- News

- Shop

- Events

-

Find out about:

-

Members Area:

- TVRCC Forums

- National Members Events >

- TVRs in print

- Digital Sprint Magazines

-

Archives

>

- Archives - Brochures

- Archives - Factory

- Archives - Pre M

- Archives - M Series

- Archives - Tasmin Wedge

- Archives - Tuscan Racer

- Archives - S Series

- Archives - Griffith

- Archives - Cerbera

- Archives - Chimaera

- Archives - T350

- Archives - Tamora

- Archives - Tuscan

- Archives - Sagaris

- Archives - Prototypes

- Archives - Rover V8

- Archives - Miscellaneous

- Add to Archives

- Technical >

- Committee >

- Travel Tours >

- Benefits

- Insurance

- Valuations

- Trade links >

- RO Resources >

- Logout

- Contact Us

RSS Feed

RSS Feed